The Situation

Biobased composites consist of a thermoplastic or duroplastic matrix reinforced with a natural fibre. This is currently done by replacing the fossil-based fibres or matrices with bio-based materials. However, since the technical requirements of the finished products are not met, or the production costs are too high, they are usually rejected.

The Project

With the manufacturing method "System4Green", existing products can be manufactured with up to 100 % renewables. Requirements for these products are usually:

- Fire retardant properties

- Thermal and hydro stability

- anti-mould properties

Suitable additives can achieve those and minimize deficits. Some renewable materials have even better properties than conventional composites. System4Green was tested on two reference products:

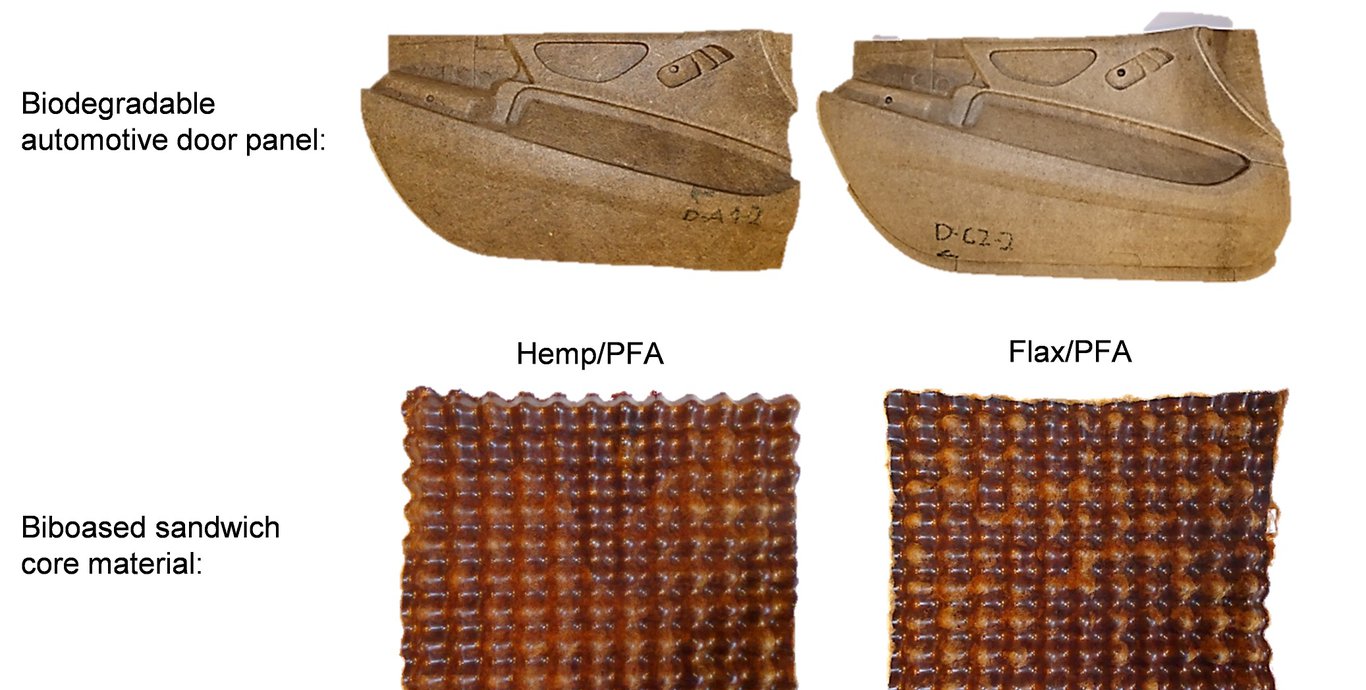

- an automotive interior door trim material: a biodegradable thermoplastic composite made of natural fibres and PLA

- the core material for a lightweight sandwich panel - material: a biobased thermoset composite of natural fibres and furan resin

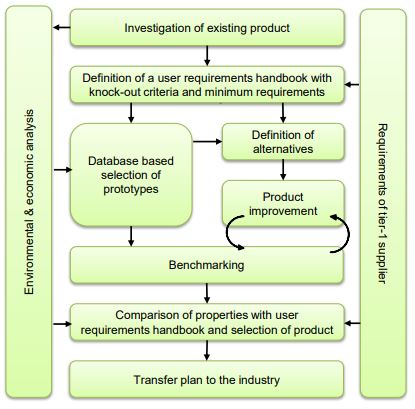

It turned out that the environmental properties of the traditional composite (natural fibres and polypropylene) are better than those of the bio-based composite with PLA because of the high energy needed for PLA production. However, the biobased thermoset composite with furan resin had the best environmental properties. The production costs of biobased composites are approx. 1.7 % - 2 % lower than those of conventional reference products. The System4Green method is suitable for systematically replacing existing products with bio-based products. To develop efficient material in the future, the method has been further developed and a database-based selection of materials has been added.

© ITA

For further information, please contact

Frederik Cloppenburg

frederik.cloppenburg@ita.rwth-aachen.de

+49 241 80 24714

Funding

Industrial Collective Research (IGF) - No 139 EN